The LigerBots always run preseason technical training in robot fundamentals for new students and advanced technical training for our returning members. But, this year, we have greatly increased the number and scope of our projects so that our many new team members will be ready to help build a competitive robot when the new game is revealed in January.

Thanks to a concept conceived by a LigerBots veteran we have two teams of rookies getting immediate hands-on experience by constructing two FTC robots. These are the 18″ robots that compete in the FIRST Tech Challenge program later in the fall. Although we will not be competing with our FTC robots, seminars given by team mentors in drive mechanisms, gear boxes, elevators, arm manipulators, programming, and the integration of the various mechanical systems will allow students to make informed engineering choices that will allow these mini-robots to be fully functional in about six weeks. Then we’ll take the robots apart and give another group of ten to twelve students the opportunity to learn and build.

Our CTO, whose leadership of the electrical sub-team was instrumental to the team’s success last year, has organized a fall training program in electrical engineering. Team members are learning fundamentals of electrical and pneumatic components, and about the FIRST rules for required electrical components.

We also are offering hands-on soldering and wire-crimping practice by having students create “brush-bots,” a component of a popular activity we do with younger students at our outreach events.

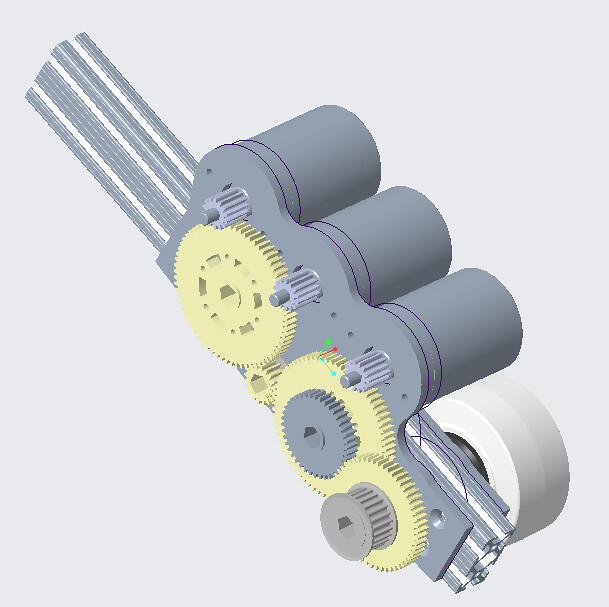

Last year we designed our robot’s gearbox for speed and maneuverability. This year we are running project in the design of a new gearbox with a different emphasis: more rotational force (torque), which would help us compete well if the 2019 robot game demands pushing either robots or heavy obstacles on the playing field. We will try to fit our motors over the robot wheels to save space inside the robot for other components, and will test whether we have to weaken our robot’s metal frame when we make the necessary frame changes. Rookies will learn how to cut out the metal plates for the gear box on our computer numerically controlled (CNC) mill and will assist with assembly and testing.

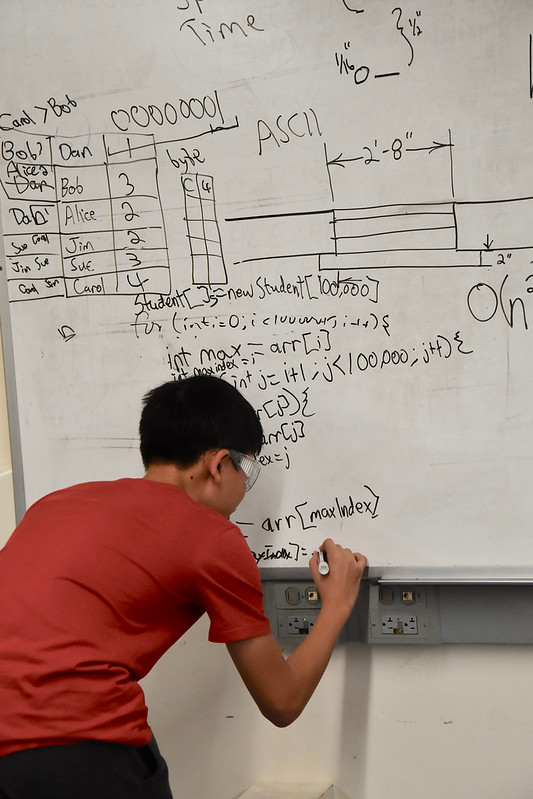

Since our robot must use software instructions to carry out its complex actions automatically, we need a strong LigerBots programming group. We are using Arduino micro controllers to help students learn how to use sensors to detect their environment and instruct actuators to affect that environment. Arduinos are especially suitable for this kind of teaching because they are simple and because there are lots of web tutorials in how to program them. We have two team veterans and a mentor, all with experience in Arduino programming, tutoring our rookies.

We have many more technical projects planned, including design of a swerve drive and an H drive, design of a ball-shooting turret to attach to the 2016 robot we use for outreach, assembly of a quadrocopter, basic training in computer aided design (CAD), practice in drilling and milling, and rewriting of the 2016 robot code in a different computer language (changing it from C++ to Java.)

We hope that our team members will be able to use all of the knowledge they gain over the next three months in these technical training sessions to build a game-winning 2019 robot!