Build season has ended, and we’ve bagged the robot! On bag day, the team must stop working on the robot, place it into a large plastic bag, and send timed photographs of the process to FIRST to prove we have bagged it before the deadline. From then on, the team can work on our second robot, as well as a 30 pound section of the first robot that we have withheld from the bag.

The bagging of our 2017 robot, with a build leader inside the bag

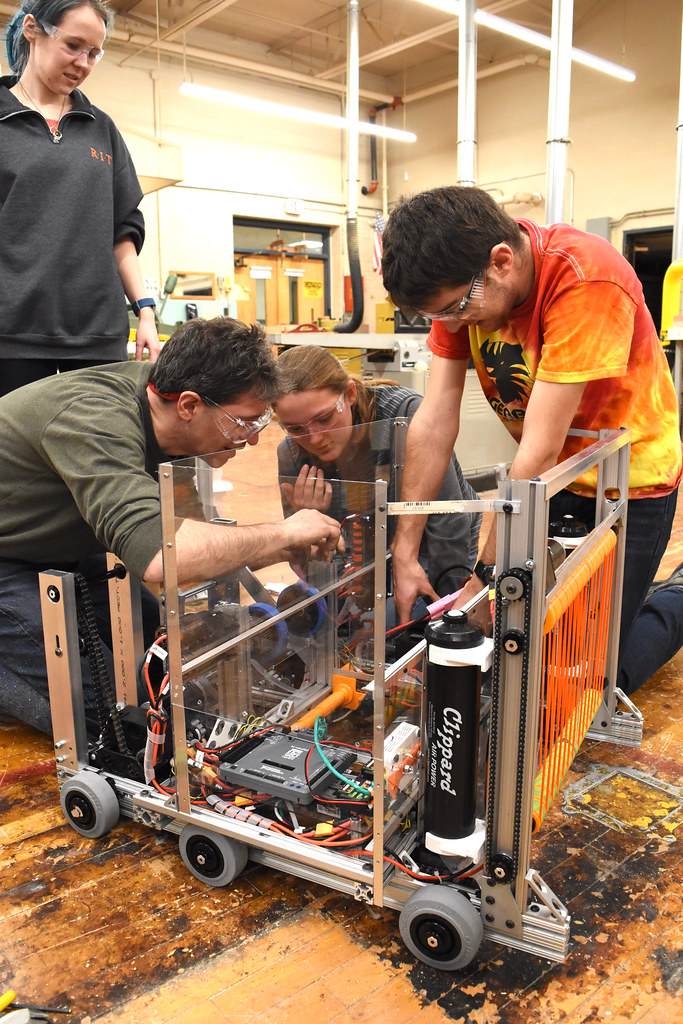

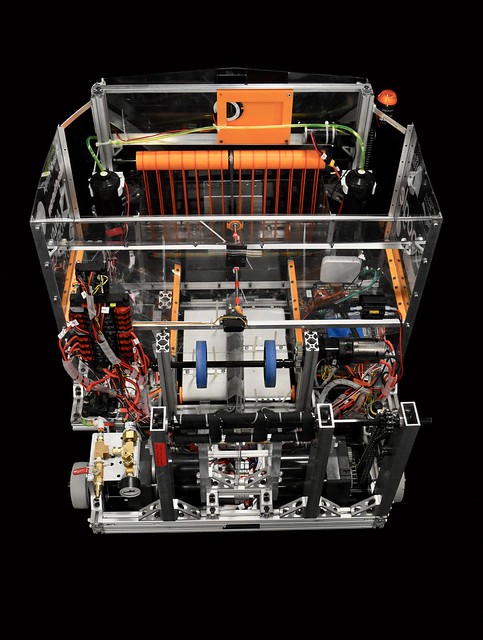

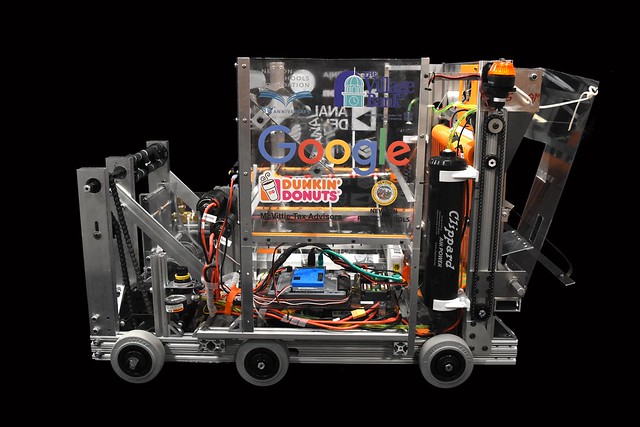

Many finishing touches were added to our robot during the last week of build. We attached a mechanism that allows it to place big, plastic game piece gears onto a long peg. We also added a polycarbonate guide to our ball shooter that dramatically improved its aim.

LigerBots finishing up our 2017 robot

We installed not one, but two cell phones on the robot. We are able to use their cameras to help place the gears and to shoot wiffle ball game pieces into a funnel shaped goal. The coding team reprogrammed the Android phones’ entire operating systems to allow two phones to be tethered to a single computer.

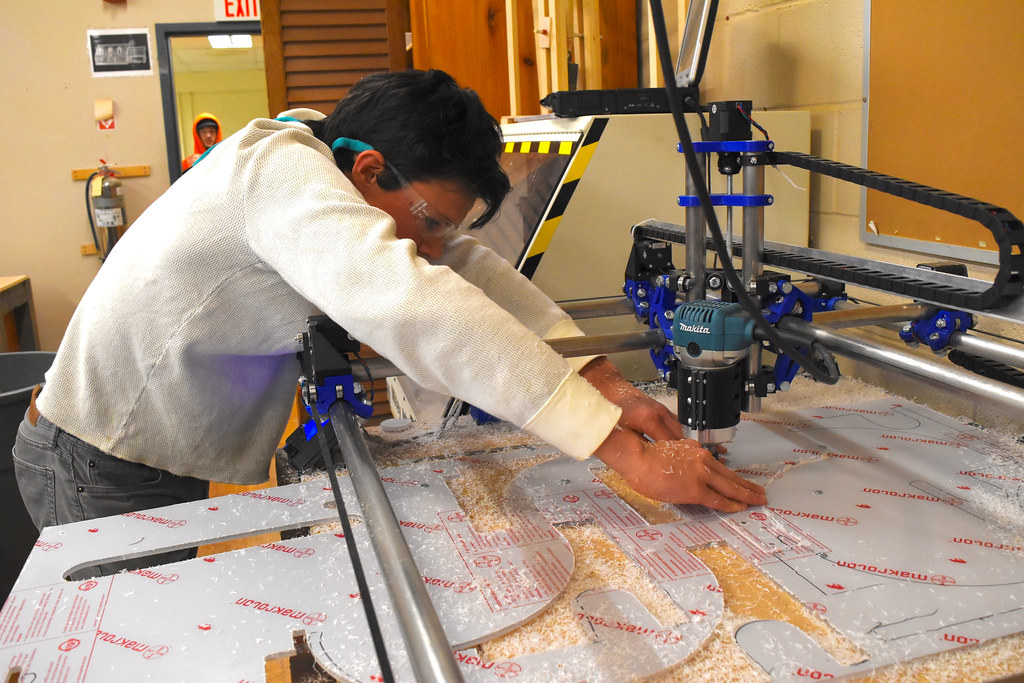

Repeated testing is a vital part of any engineering project. The LigerBots tested each of the mechanisms throughout the entire build process. The ball shooter was improved over and over until it could accurately shoot four wiffle balls per second. The gear-placing mechanism was improved until its vision tracking could auto-align and drop off a gear in less than five seconds. This year we made a big leap up in the precision of our curved surfaces and large plastic and metal plates by using a Mostly Printed Computer Numerically Controlled (MPCNC) 2.5D router that we assembled ourselves to manufacture many of our robot parts.

The team was extremely glad to see hours and hours of hard work pay off.

A LigerBot using our MPCNC 2.5D router

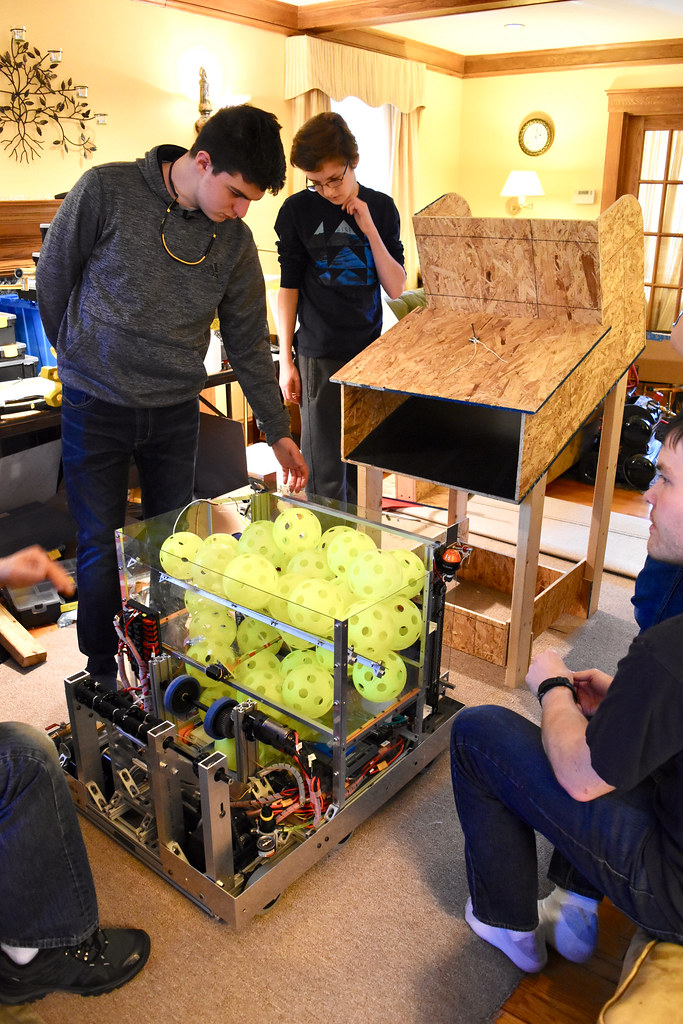

LigerBots testing the ball shooter

Although bag day occurred during school vacation, many team members stayed in Newton to work on the robot rather than going on vacation. We drove the robot back and forth from the homes of coaches to Newton South, depending on whether we could get into our school shop. It was a hectic process, but at 10:22 p.m. on Tuesday, the team cheered as one of the build leaders followed the robot into the giant plastic bag to make sure it was placed correctly.

LigerBots testing a dump of whiffle balls into the robot’s hopper, at a coach’s house over February vacation

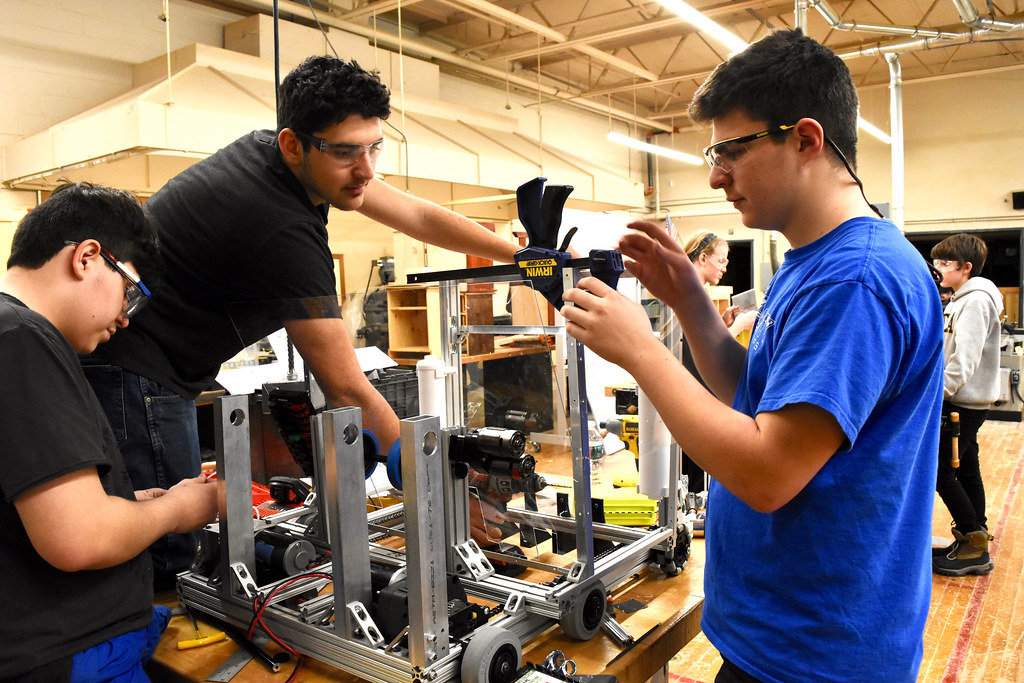

After bagging the first robot, the team was able to catch up with construction of the second robot so that it now matches the original. We are now free to test additional improvements in preparation for the two competitions coming in the next three weeks. We are lucky to be able to have a second robot thanks to donations from our many sponsors and donors.

LigerBots working on the second robot

Even our Liger mascot got in on the robot build action!

The LigerBots 2017 robot, Daedalus